01. Requirements

We make sure that the design you give us is good to go – structurally feasible, materials & hardware selected, and the cabinet doors & drawers configured.

We make sure that the design you give us is good to go – structurally feasible, materials & hardware selected, and the cabinet doors & drawers configured.

We measure each space in detail. Every bulge, slant, and obstacle will be noted.

We often see projects fabricated on wrong measurements. With our 12-point measurement system, this will never happen.

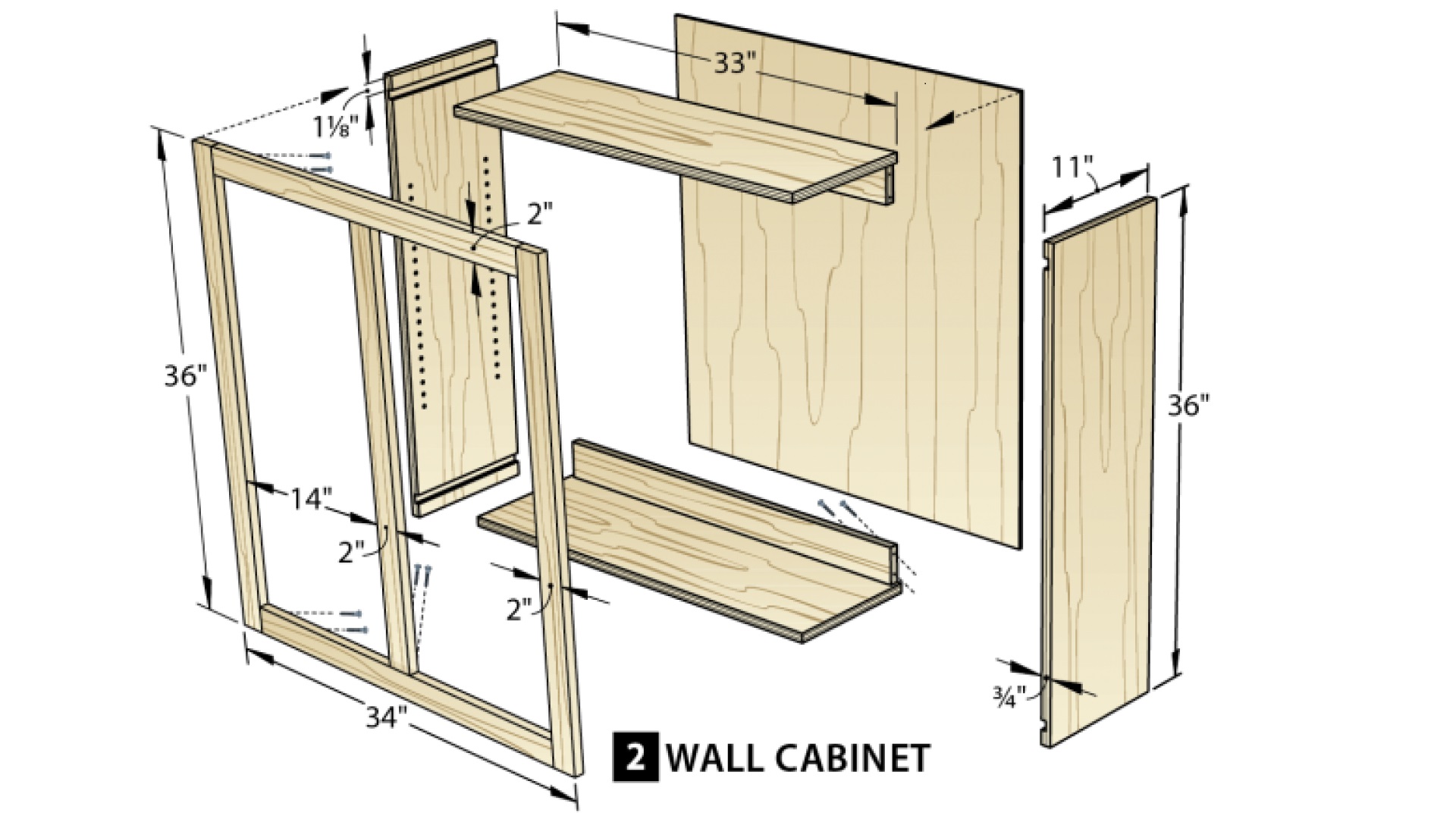

We deconstruct each piece of carpentry into carcass plans, doors & drawers plans.

Some carpenters (even experienced ones) wing it and ad-lib, but we believe planning is a crucial step before cutting the first piece of wood.

We measure our cuts and check against the plans — every millimeter counts. We also check square-ness — every corner must be 90°, not 89°, not 91°.

We mock up the assembly in the factory to make sure everything is fabricated to specification.

More than just fastening cabinets onto the wall, we make sure that the carpentry is well-aligned to the space. Every cabinet is plumb, square, and level.

After installation, we clean up the place to get rid of excessive wood dust.

Before handover, we quality check our own work to take note of all defects. We send this list to you together with a timeline for touch up and rectifications.

Then, we do a walkthrough with you to see that everything is exactly the way it should be.